ECO-DESIGN, A TOP PRIORITY

Our 11 eco-design criteria

Gerflor has elaborated a set of guidelines based on 11 eco-design criteria covering the life cycle of our products. The goal is to manage a product's carbon footprint starting with the very first pencil stroke, the first essential step in a circular economy.

1 Responsible purchasing of raw materials

2 Use of renewable raw materials

3 Energy requirement per m²

4 Production scrap rate

5 Load volume optimisation

6 Weight reduction per m2

7 Adhesive free products

8 VOC and volatile reduction

9 Minimised use of cleaning products

10 Recycled material in our products and packaging

11 Recyclability of our products and packaging

Floors that last

Average life span of 25 years

One of the best ways to preserve our planet’s resources is to offer products that last a long time. At Gerflor, we consider our products as durable capital goods that fulfill their technical and aesthetic function for years and even decades.

Gerflor formulations are 100% REACH* compliant

- No heavy metals

- No formaldehydes

- No solvent-based inks

- No PCP (pentachlorophenol)

- No CMR content (carcinogenic, mutagenic, reprotoxic)

- No other substances prohibited by Reach

*REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is a European regulation listing chemical substances with potential impact on human health. The list is managed by the ECHA (European Chemicals Agency).

Know more about REACH

Continuous life cycle analysis

Gerflor products all have an Environmental and Health Declaration Sheet (FDES), which, among other information, presents the carbon impact at each stage of the product’s life. This policy enables our engineers to set relevant eco-design targets, and allows our customers to evaluate the environmental impact of our products. The FDES documents are available on www.inies.fr.

OUR BIOSOURCED SOLUTIONS

Gerflor has innovated over the years by integrating new raw materials in its products, notably biosourced materials.

As early as 2002, Gerflor launched the SAGA2 range with its backing made of cork, a biosourced material that also offers exceptional acoustic properties.

In 2011, the Mipolam Symbioz range of homogeneous floor coverings was manufactured using 100% biosourced and renewable plasticisers made from cereal crop residue.

Since 2018, this commitment has been further strengthened by integrating DLW Linoleum manufacturing within the Gerflor Group.

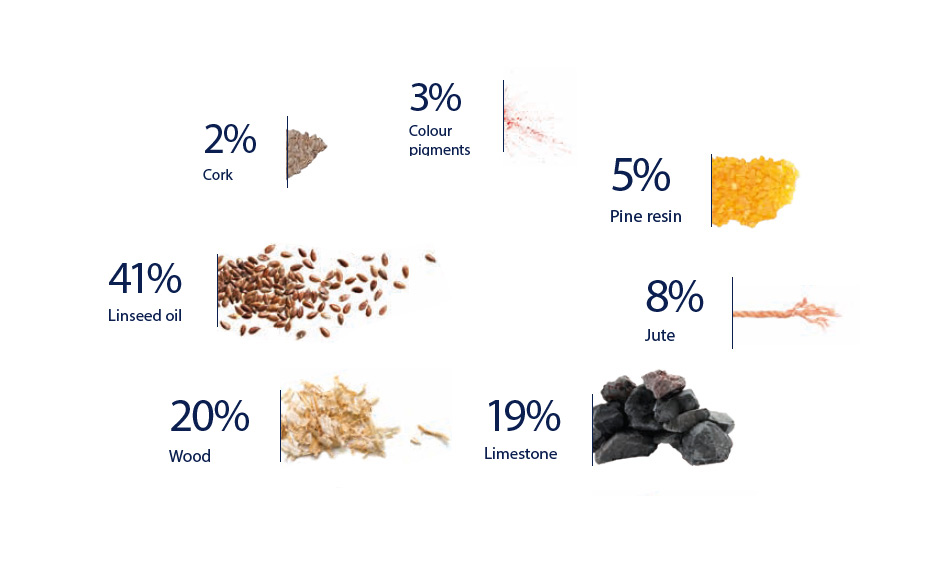

The special case of Linoleum

Because nature is our greatest source of inspiration, the DLW Linoleum collection offers architects a choice of 159 nature-inspired colour options to feed their creativity while respecting the environment.

Made in Germany since 1882 and “Cradle to Cradle certified™ Silver”, DLW Linoleum is composed of 98% biosourced or mineral materials such as linseed oil, wood flour, chalk, jute and pine resin. This is an eco-friendly product, with 76% of its raw materials renewable rapidly. Linoleum also helps preserve nature, as it contains up to 40% recycled materials and is 100% recyclable (industrial scrap and laying offcuts).

This is how we connect people with nature.

World Leader

Floor covering solutions

Responsible

Recycled materials, recycling of end-of-life products, ISO14001

Multispecialist

Specific responses to the needs of twenty market segments

Expert team

Commitment to the success of our customers

Customer success

Daily commitment to guarantee our customers total quality and competitiveness.